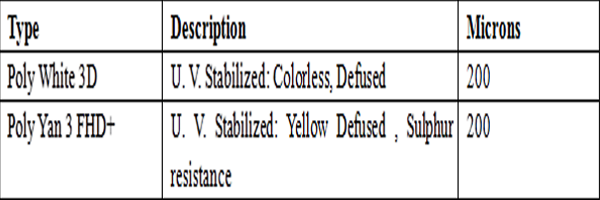

Poly film Information:

Polyhouse Paper/ Poly film/ Polyhouse FilmTechnical Information:

Size: 4.5 Mtr & 5.5 Mtr

POLYHOUSES AND ITS IMPORTANCE

The polyhouses are constructed with the help of ultraviolet plastic sheets, so that they may last for more than 5 years. The structure is covered with 1501 m thick plastic sheet. The structure is prepared with the bamboos or iron pipes. Iron pipe structure is costly but more durable than bamboo.Generally the length of the polyhouse is 25-30 feet and width 4-5 feet. The direction of polyhouse is always East to West, so that the maximum sunshine is available. The house should not be constructed in shade. The size of polyhouse may differ depending on the necessity. The polyhouses are kept cold or hot depending upon the season.

Use of Polyhouses:

From the point of view of earning more profit only such off-season crops should be grown, which are being sold at higher prices in the market. Big hotels in cities are mostly in the need of off-season vegetables and so is the case with some prosperous people in big cities. In such areas and also in the hill and remote regions where fresh vegetables are required regularly for meeting out the requirements of security forces, the construction of polyhouses is more lucrative and is a must. The crops grown under the polyhouse are safe from unfavourable environment and hailstorm, heavy rains or scorching sunshine, etc. Crops of the polyhouse can be saved from birds and other wild animals. The humidity of polyhouse is not adversely affected by evaporation resulting in less requirement of water. In limited area of polyhouse, insects and pests control is also easy and less expensive. By adopting the modern technology of polyhouse, the difference in the demand and supply of off-season vegetables and fruits etc. can be minimised. This facilitates in maintaining the quality of the product also.Polyhouse can be used for:

- Producing half hardy perennials or bedding annually grown from seed both during sowing and pricking out.

- Protect tender plants and bulbs during the winter months.

- Grow hobby plants such as chrysanthemums, fuschia's or exotic orchids.

- Cultivate indoor pot plants.

- Cultivate alpine species.

- Use it for commercial purposes.

THE EXPECTED BENEFITS ARE:

Technical: The determination of the most cost effective method for limiting greenhouse humidity. The development of a new and effective way of controlling plant irrigation, which could have application on open field cultivation as well. Tuning heating system efficiency with the phase of the protected crop. Standardisation of conventional sensors and development of new sensing techniques to enable "quality control" in prime production. Advanced concepts of Information technologies to provide a vehicle for speeding up the transfer of research results to practice.Scientific:

The development of a method of predicting plant water and nutrient requirement based on easily measured weather variables. A significant advance in the simulation techniques used to predict the environment in cropped enclosures. Innovative sensing of plant physiological responses, including early nonvisible symptoms of disease onset. The development of on-line techniques for the real time optimisation, cost vs quality-grade, of controlled conditions.

Economic:

Reduction of precious water and nutrient chemicals consumption, by an amount of up to 40% in greenhouse production and ensure quality by water availability and balanced nutrient supply. This will be of particular importance in regions of scarce water. Reduction of labour cost and pesticides with the "soilless closed irrigation" systems. Optimal control of greenhouse humidity and of energy utilisation will enable grower income be maximised. An integrated product will satisfy constraints for both; the private competitiveness and the public benefit.

Environment:

A reduction in pollution caused by the fertilisers contained in excess irrigation water drained to the soil. Reduction of crop protection chemicals (reaching the consumer directly through the product and indirectly through the environment) by: controlling humidity, early detection of diseases, and finely controlled closed irrigation systems.

FULLY COMPUTERIZED CONTROL SYSTEM

Most of the time, the owners prefer Mutually Controlled System or Semi Automatic Controlled System for green house, because of low investment. But in such type of Control Systems it requires a lot of attention and care. Also it is very difficult and cumbersome to maintain uniform environment inside the Green House. Ultimately this affects crop production, non uniform growth and low quality of the crop. Computerized Control System is the solution to come over this problem and to maximize returns. Computer provides a faster and precise operation in the Green House. Also it stores, displays and prints the Green House information as needed. Computer can do the following operations as per the pre-scheduled programme:- 1. Starting and closing of Micro Irrigation System.

- 2. Application of Liquid Fertilizer or Water Soluble Fertilizer (N:P:K) and other Nutrients to the plant.

- 3. Operation of Misting System as required.

- 4. Opening and closing of ventilators and side wall roll up curtains as needed.

- 5. Operation of shading net / Thermal screen.

- 6. Operation of cooling pad and fan.

- 7. Operation of heating system.

- 8. Operation of CO2 Generator, Climate Control, Temperature, Humidity, Heat Radiation, Control of EC, PH, PPM level in irrigation water etc. as required to the plant.

Benefits:

- 1. Optimised Humidity control

- 2. Irrigation and water saving

- 3. Nutrients supply

- 4. Quality

- 5. Energy conservation

- 6. Development of a modern Management and control package.